Noris Plastic

Who we are:

Your expert for plastics processing and mechanical engineering.

Mechanical engineering

Learn morePlastics processing

Learn moreComplete extruder systems

Learn moreExtruder rental and leasing

Learn moreMechanical engineering

Extrusion lines – customized & efficient

Plastics processing

Profiles, tubes, winding cores – precision in series production

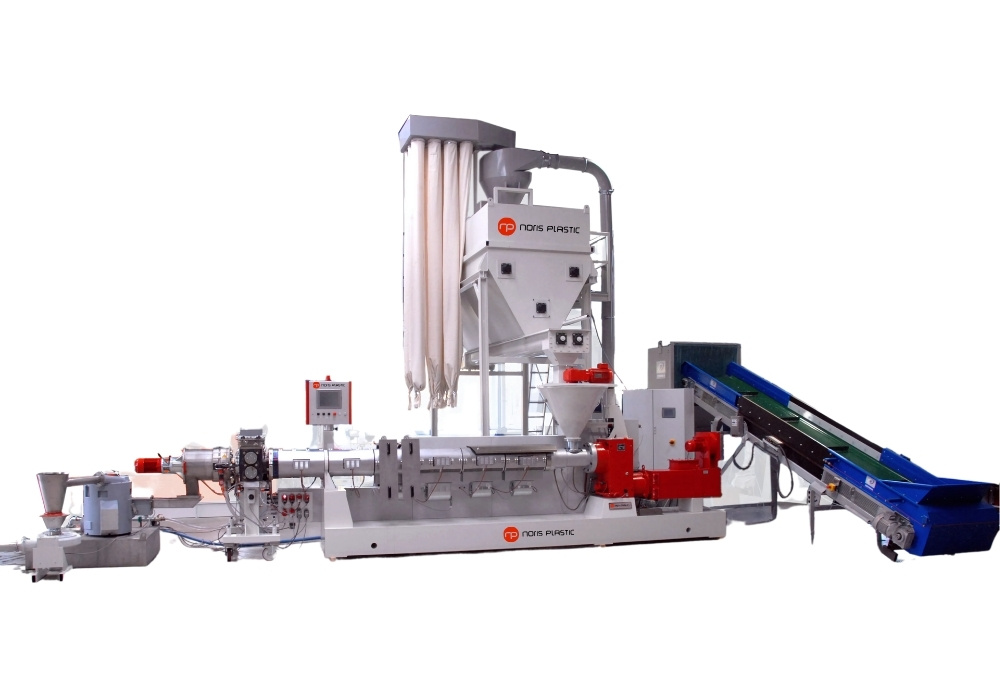

Complete extruder systems

Extrusion projects require more than just machines – they need well thought-out systems. That’s why we plan and supply complete extrusion systems that are precisely tailored to your requirements.

From the material feed to the downstream unit: we configure every detail so that it works perfectly in your process. We can also take care of installation, commissioning and training on request – all from a single source.

Complete solutions – perfectly tailored to your application

Extruder rental and leasing

Sometimes budgets are cut, or a new project poses challenges for the existing infrastructure. It may also be that an extruder needs to be thoroughly tested before it is purchased. If you want to remain flexible in such cases and keep the cost structure manageable, rental or leasing contracts are a good option.

Flexible solutions for test runs and project launches

Technical center, training. Consulting

We support our customers with individual know-how – through training, technical advice and the opportunity to carry out material and production tests under real conditions. Our in-house technical center is available for this purpose, where we work together to optimize processes, test new materials and further develop extrusion solutions. This creates knowledge that works – directly in your application.

Innovation up to date

Twinflex combines extruder and rolling mill

As part of our diverse research cooperations we have developed a non-combing, tangential twin-screw extruder with the Chemnitz University of Technology, which has been patented since the beginning of 2021. The Twinflex is based on a system that offers a great deal of freedom in terms of direction of rotation and speed variability. The variable peripheral speed of the two screws in relation to each other allows the shearing speed in the plasticizing process to be adapted to the material to be processed. This enables very gentle processing, even of renewable raw materials. The Twinflex combines the functions of a single screw, twin screw and rolling mill, which guarantees a high level of investment security and flexibility.

Not necessarily a contradiction

Sustainability and

Plastics

Plastic is a very double-edged sword – there are many applications that are unnecessary and contribute to today’s problem with microplastics and the like. In the world of technical plastics in particular, however, which are recycled to a large extent, there is hardly a more sustainable alternative. Since the company was founded in 1969, we have thought about and carried out recycling in order to reuse production waste and rejects.

In 1990, we produced the first winding cores made from 100 percent recycled material for suitable applications. The circular economy has long been part of our everyday work, and we support customers in implementing future-proof sustainability concepts.