Twin screw extruder

Twin screw extruder from Noris Plastic

Twin screw extruder from noris plastic – flexibility meets innovation

Synchronized or tangential? Modular and individual.

Twin-screw extruders from noris plastic stand for maximum adaptability, efficiency and process reliability – whether combing or non-combing. Our machines can be configured precisely to your specific requirements. Since summer 2021, we have been expanding our portfolio with a pioneering technology: the non-intermeshing, tangential twin-screw extruder, developed in cooperation with Chemnitz University of Technology. This patented system impresses with its variable screw rotation direction and innovative process control.

Synchronized intermeshing twin-screw extruder

Our intermeshing twin-screw extruders are characterized by a modular design of barrel and screw. This enables maximum flexibility – both in the planning phase and for later modifications. In addition to classic conveying and kneading elements, numerous special elements are available to optimize the extrusion process in a targeted manner.

We also offer a wide range of materials for screws and barrels, so that even abrasive or corrosive materials can be processed safely. The combination of durable design, simple maintenance and fast availability of spare parts ensures a high level of investment security and process stability.

- Screw diameter: 20-60 mm

- Process length: modular from 32 to 48 L/D

- Screw speeds: 600-1200 min-¹

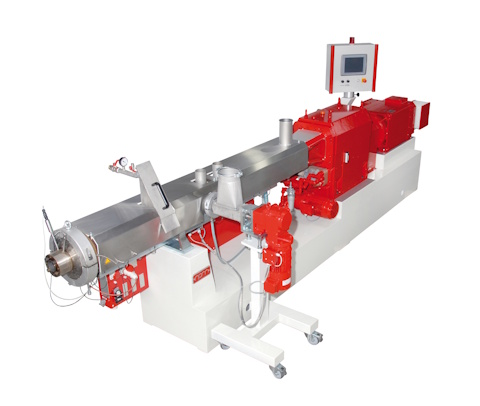

Twinflex – extruder and rolling mill in one – our patented innovation.

With our patented Twinflex, noris plastic is setting new standards in twin-screw technology. By varying the direction and speed of rotation of the screws in relation to each other, the shearing speed can be optimally adapted to the material to be processed. This enables particularly gentle plasticizing – ideal for sensitive raw materials such as natural fibres or bio-based materials.

The Twinflex combines the properties of a single-screw extruder, twin-screw extruder and rolling mill in one system – a genuine innovation with a wide range of applications and high investment security.

- Screw diameter: 25-60 mm

- Process length: 40-50 L/D

- Screw speeds: up to 750 min-¹

Our twin-screw extruders at a glance

noris2S-20: The smallest compounder in the series

noris2S-25: From the recipe to small series production

noris2S-34: Changing batches and recipes

noris2S-42: Masterbatches, Compounding & Co.

noris2S-60: The production compounder

Twin screws noris2S-20

Ideal for small batches, short changeover times and simple operation: the noris2S-20 is the perfect introduction to twin-screw technology – compact, precise and flexible.

Specs at a glance:

- Screw diameter: 42 mm

- Process length: 46 L/D

- Throughput capacity: approx. 15-500 kg/h*

* Guide value: Throughput depends on process, material and recipe.

You can download the data sheet here.

Compact & efficient: The smallest compounder in the series

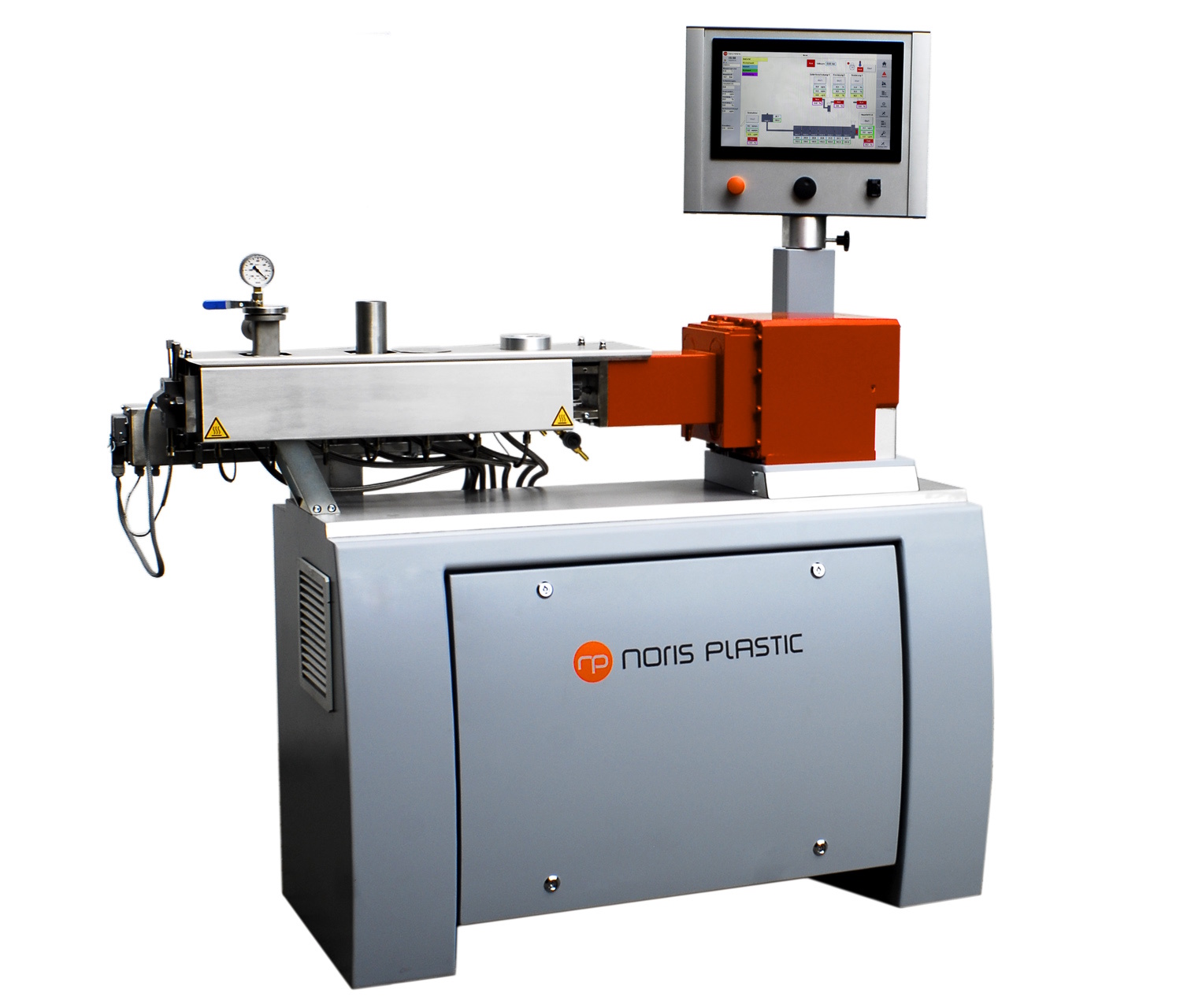

noris2S-25 twin-screw extruder

The noris2S-25 twin-screw extruder is the right solution when it comes to formulation development, basic research or small-scale production and larger batch sizes are required.

Specs at a glance:

- Screw diameter: 25 mm

- Process length: 52 L/D

- Throughput capacity: approx. 2 to 125 kg/h*

* Guide value: Throughput depends on process, material and recipe.

You can download the data sheet here.

Recipe development & small series production at a high level

noris2S-34 twin-screw extruder

The noris2S-34 twin-screw extruder is particularly suitable for processing changing batches and recipes. It really comes into its own when it comes to fast product changes for small to medium batch sizes or when the focus is on short production times.

Specs at a glance:

- Screw diameter: 34 mm

- Process length: 46 L/D

- Throughput capacity: approx. 5-350 kg/h*

* Guide value: Throughput depends on process, material and recipe.

You can download the data sheet here.

Fast product changes with changing recipes

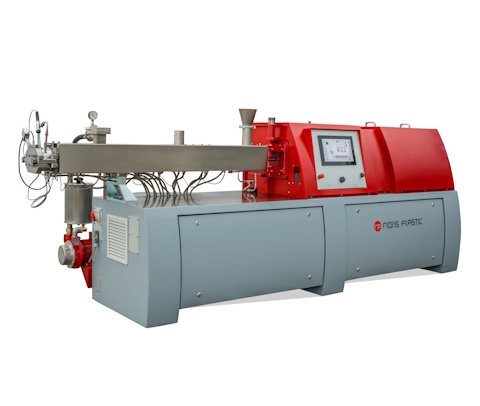

Twin-screw extruder noris2S-42

The noris2S-42 twin-screw extruder combines the functionality of the noris2S-34 with the performance of the noris2S-60. One focus is the processing of polymer materials in masterbatch production, compounding or processing. Applications for non-polymeric materials in the pharmaceutical and cosmetics industries complete the range of possible applications.

Specs at a glance:

- Screw diameter: 42 mm

- Process length: 46 L/D

- Throughput capacity: approx. 15-500 kg/h*

* Guide value: Throughput depends on process, material and recipe.

You can download the data sheet here.

Versatile all-rounder for masterbatch & more

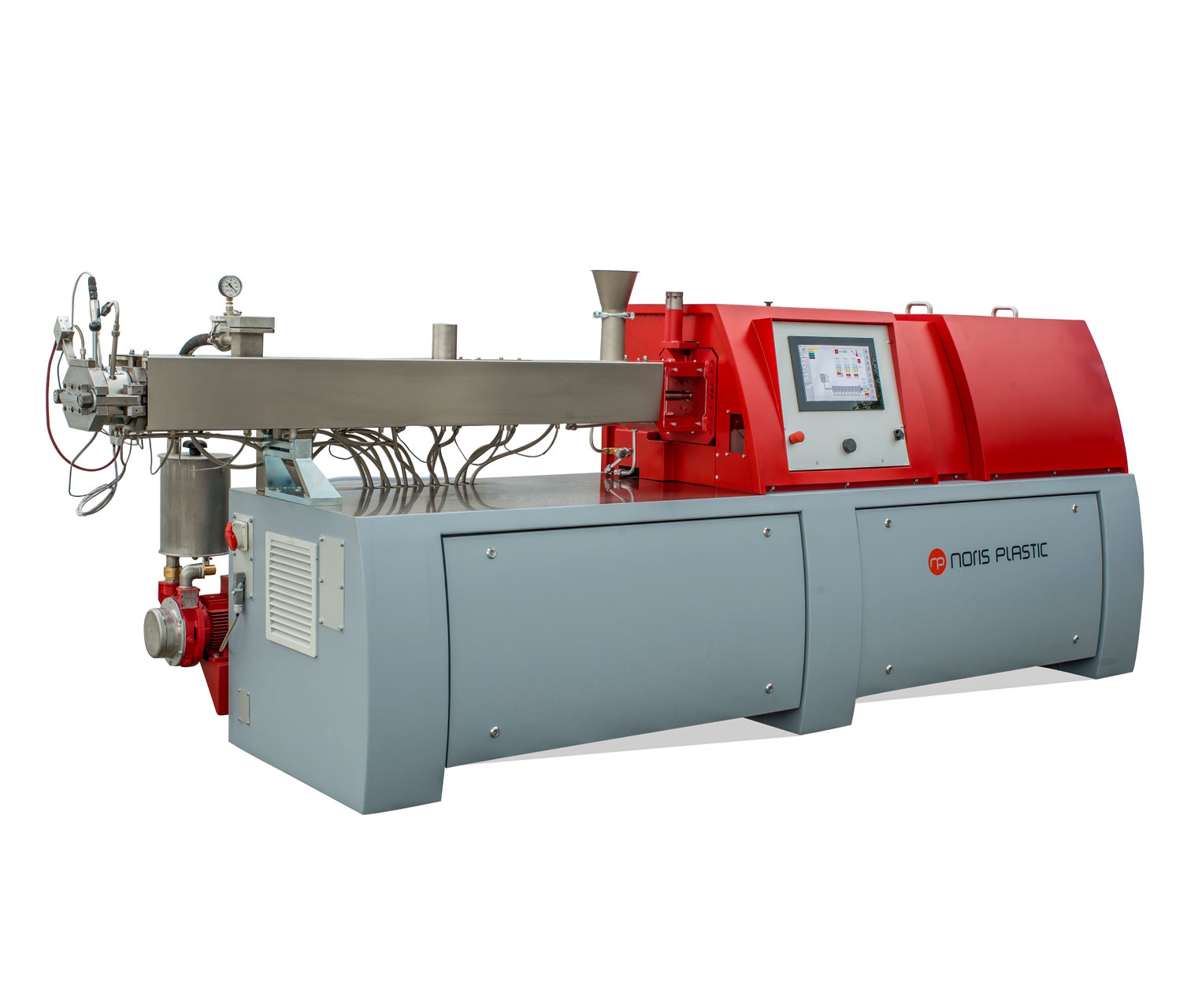

noris2S-60 twin-screw extruder

The noris2S-60 twin-screw extruder is the typical production compounder, including quick changeover and easy cleaning. The modular design with excellent accessibility of the individual units ensures adaptation to almost any processing task.

Specs at a glance:

- Screw diameter: 60 mm

- Process length: 44 L/D

- Throughput capacity: approx. 200-1500 kg/h*

* Guide value: Throughput depends on process, material and recipe.

You can download the data sheet here.

High production & modular: The most powerful compounder