Winding cores

Customized precision meets industry-leading innovation

Winding cores ||Winding cores

Winding cores from Noris Plastic

In the world of modern manufacturing, winding cores play a crucial role by supporting a variety of industrial applications with precision and reliability.

At Noris Plastic, we understand the importance of these components and therefore not only offer standardized solutions, but also develop winding cores specifically tailored to your requirements. Our products are characterized by exceptional quality and adaptability.

Wide range of material and configuration options

Our winding cores are available in a range of wall thicknesses from 1 mm to 25 mm and inner diameters from 1 inch to 6 inches. We process a wide range of thermoplastics – from PE and HDPE to PP, PS and ABS – and also offer food and pharmaceutical compliant solutions on request. The materials can be modified depending on the area of application, for example talc-reinforced, and range from virgin material to standard material and recyclates.

Precision in production

Noris Plastic relies on maximum precision in production, with individual assemblies possible from a length of just 3 mm in our in-house cutting center – with an impressive accuracy of +/- 0.2 mm. Our winding cores meet the strictest tolerance specifications and offer optimum concentricity properties as well as the required crown pressure resistance. Thanks to flexible customization options for the body tool, we can also implement individual customer requirements economically.

Individual areas of application

Whether in food production, the pharmaceutical industry or other technologically demanding sectors – our winding cores meet the highest demands and support the safety and efficiency of your production processes. Contact us to find out more about our customized solutions and how we can meet your specific needs.

Noris Plastic – Individual winding cores and winding cores for your industrial solution

Precision-manufactured winding cores

Noris Plastic supplies first-class winding cores worldwide that are precisely tailored to the specific requirements and needs of our customers. With a wide range of diameters, materials and customization options, we ensure that every product meets the highest standards – from one-off production to mass production.

Winding cores made of polystyrene (PS)

Customized precision for demanding applications

Noris Plastic offers high-performance polystyrene winding cores that are specially designed for use in industries where durability, hygiene and optical qualities are of the utmost importance. These premium winding cores are recommended for applications in the electronics, food, pharmaceutical and medical industries.

Customizable insides for maximum flexibility

Depending on your specific requirements, we offer these winding cores with a smooth or grooved inside, ensuring optimum fit and function over the entire length of the roll.

Diverse diameters and customized solutions

At Noris Plastic, your winding core is not a standard product, but a solution perfectly tailored to your requirements. Our precise manufacturing techniques enable flexible adaptation to your needs.

- Inside: smooth or grooved

- Available diameters: 76, 77, 82, 84, 86, 88, 90, 100, 102

- Cutting length from 100 mm to 4000 mm

- Other dimensions and customizations on request

Contact Noris Plastic to find out more about our customized polystyrene winding cores and how we can design the ideal solutions for your applications.

Winding cores made of polyvinyl chloride (PVC)

Robust performance for technical applications

Noris Plastic supplies high-performance winding cores made of polyvinyl chloride (PVC), which are known for their exceptional compressive strength, temperature resistance and dimensional stability. These properties make our PVC winding cores the ideal choice for winding technical and agricultural plastic films.

Available in a wide range of diameters up to 3 inches, our products meet demanding industrial requirements with reliability and durability. The inner surface of the sleeves can be designed smooth or grooved according to your specific needs to ensure optimal functionality.

Customized configurations for your requirements

- Inside: optionally smooth or grooved

- Available diameters: 76, 77, 82, 84, 86, 88, 90, 100, 102… others on request

- Cut to length from 80 mm to 4000 mm

At Noris Plastic, every winding core is perfectly tailored to your requirements. We not only offer standard products, but also customized solutions that meet your exact requirements.

Contact Noris Plastic to find out more about our customized PVC winding cores and how we can support the efficiency of your processes.

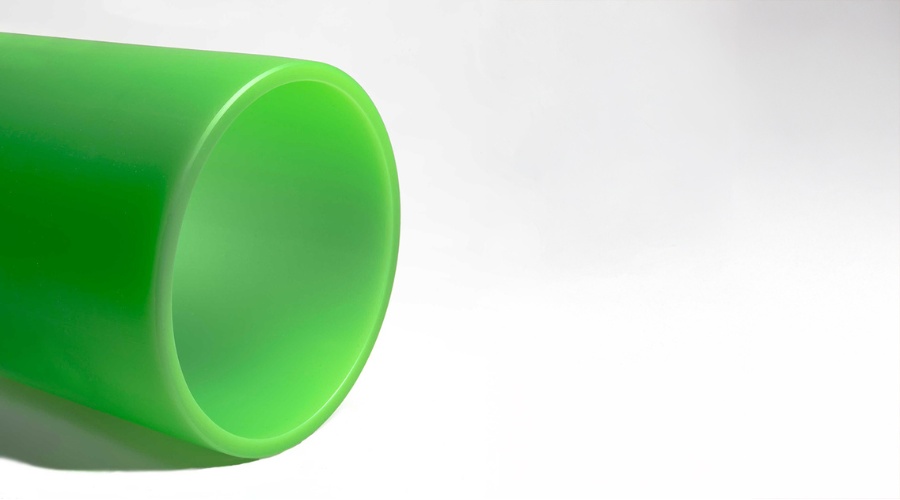

Winding cores made of polypropylene (PP)

Versatile winding cores made of polypropylene (PP) from Noris Plastic

Noris Plastic offers an extensive range of polypropylene (PP) winding cores that are known for their robustness, durability and adaptability. These cores are specially designed for winding plastic film and other industrial materials and offer solutions for a wide range of application needs.

For all our PP winding cores, we offer individual customization to meet your specific needs. Each product is manufactured with the utmost care and precision to ensure optimum results.

PP virgin material for standard and special applications

- PP virgin material 76.5 x 8.5 mm & 152.5 x 8.25 mm: With their large diameters and thicker walls, these cores offer increased strength for demanding industrial applications. Available in green and especially suitable for winding heavy duty materials.

- PP virgin material 76.5 x 7 mm: Ideal for medium-weight materials, these red sleeves are characterized by precise manufacturing and a smooth inner surface that enables damage-free handling of the material.

Sustainable solutions with PP Regenerat

PP Regenerated 76.5 x 7 mm: These environmentally friendly sleeves made from recycled polypropylene offer a robust construction without compromising on quality. Their grey color underlines the commitment to environmental protection and sustainability.

Specifications and customizations

- Inner diameter: Varies depending on the model (76.5 mm for standard models, 152.5 mm for larger sleeves)

- Wall thickness: 7 mm to 8.25 mm, depending on model

- Inner surface: Smooth, ensures efficient material handling

- Colors: Green, red, gray, depending on material type

- Tolerances: -0.5/+0.5 mm, with further adjustments possible on request

Contact Noris Plastic](/contact/)</h3> today to find out more about our customized solutions and how we can support your production processes with our high-quality PP winding cores.

ABS winding cores

Reliability and versatility in every dimension

Noris Plastic offers high-quality winding cores made of ABS, which have been specially developed for applications where strength, pressure resistance and hygiene have the highest priority. Ideal for the medical sector, these winding cores meet the strictest requirements for winding plastic film and are also food-safe.

These sleeves are available in a wide range of diameters, from 3mm up to 120mm, to ensure flexibility of application. ABS, known for its excellent pressure and temperature resistance, provides the necessary robustness and durability for demanding applications.

Customizable features for specific needs

- Inside: optionally smooth or grooved

- Available diameters: 76, 77, 82, 84, 86, 88, 90, 100, 102… others on request

- Cut to length from 80 mm to 4000 mm

Each winding core is manufactured precisely to your specifications to meet your specific needs. Noris Plastic transforms your requirements into unique, customized solutions.

HIPS winding cores with four internal grooves

HIPS winding cores – for demanding winding processes

Noris Plastic offers innovative winding cores made of HIPS (High Impact Polystyrene), which have been specially developed for their improved gripping and holding functions. These cores are characterized by a wall thickness of 5 mm and are equipped with four internal grooves, making them ideal for demanding rewinding processes. The careful design ensures high functionality and efficient handling in industries that require high precision.

Customizable insides for optimal functionality

The inside of these sleeves can be designed specifically for the needs of your production processes to ensure the best fit and function.

Customized solutions for your requirements

- Inside: Grooved

- Available diameters: 76.5 mm

- Wall thickness: 5 mm

- Color: Nature

- Cutting length: From 80 mm to 4000 mm

- Further customizations on request

Contact Noris Plastic</h3> to find out more about our customized HIPS winding cores and how we can increase the efficiency of your processes.

Winding cores made of PE Antistatic

Safety and efficiency for the electronics industry

Noris Plastic presents the antistatic winding cores made of PE, which are specially designed for use in electronics production. With a wall thickness of 6 mm, these black cores offer additional safety when handling electro-sensitive materials. The antistatic finish effectively minimizes static charges, making them ideal for applications that require the highest standards of safety and precision.

Flexible adjustments for maximum safety

These sleeves can be customized to specific industrial needs to ensure optimal results.

Customized solutions for your requirements

- Inside: Smooth

- Available diameters: 76.5 mm

- Wall thickness: 6 mm

- Color: Black

- Cutting length: From 80 mm to 4000 mm

- Further customizations on request

Contact Noris Plastic</h3> to find out more about our customized PE antistatic winding cores and how we can meet your specific needs.